What is Oxidized or Blown Bitumen?

Oxidized bitumen or Blown Bitumen, also known as blown bitumen, is produced by introducing hot air into pure bitumen during the final stages of its refinement. In this process, air at a temperature of 200 to 300 degrees Celsius is passed through a perforated pipe into the bitumen container. This causes the hydrogen atoms in the bitumen’s hydrocarbon molecules to react with oxygen, leading to a process called water polymerization. This article delves into the properties, applications, and types of blown bitumen to provide a comprehensive understanding of this material.

Builders who understand What Is Bitumen can better utilize it in sustainable and long-lasting projects.

What is Oxidized Bitumen?

To begin, let’s define blown bitumen and explore how it is produced. Oxidized bitumen, often referred to as blown bitumen or blown asphalt, is derived from petroleum through a process that involves controlled chemical reactions with air or oxygen at elevated temperatures. This process enhances the stickiness and hardness of bitumen, significantly improving its heat resistance and overall properties.

Manufacturers can adjust the degree of oxidation to create various grades of oxidized bitumen with unique characteristics. These include a higher softening point, lower penetration degree, and improved resistance to air and further oxidation. Due to these properties, blown asphalt finds widespread applications in roofing, waterproofing, and the production of industrial products such as adhesives, coatings, and sealants.

How is Oxidized Bitumen Made?

Blown asphalt, or oxidized bitumen, is created by consistently blowing air into normal bitumen. The process begins with heating penetration-grade bitumen in a controlled environment. Once heated, air is blown into the bitumen to manage its petroleum content during oxidation. This method produces various grades of oxidized bitumen, each tailored for specific applications.

What is the Process of Bitumen Oxidation?

The production of oxidized bitumen involves several key steps:

- Heating: Bitumen or vacuum residue is heated to a temperature between 200 and 270°C.

- Transfer: The molten bitumen is transferred to bitumen-blowing towers.

- Air Injection: Air is blown into the bitumen to initiate the oxidation process.

- Cooling: The hot oxidized bitumen is cooled using air.

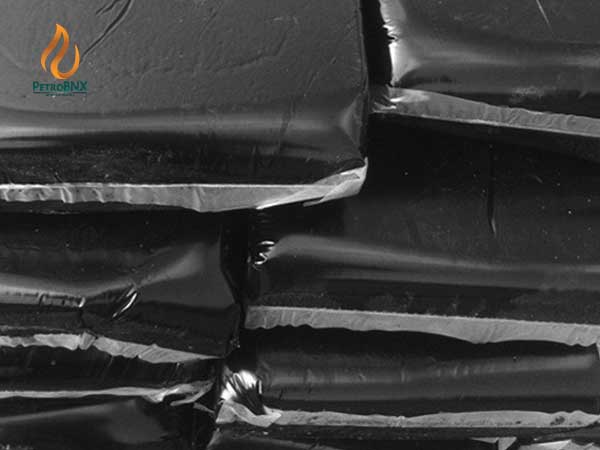

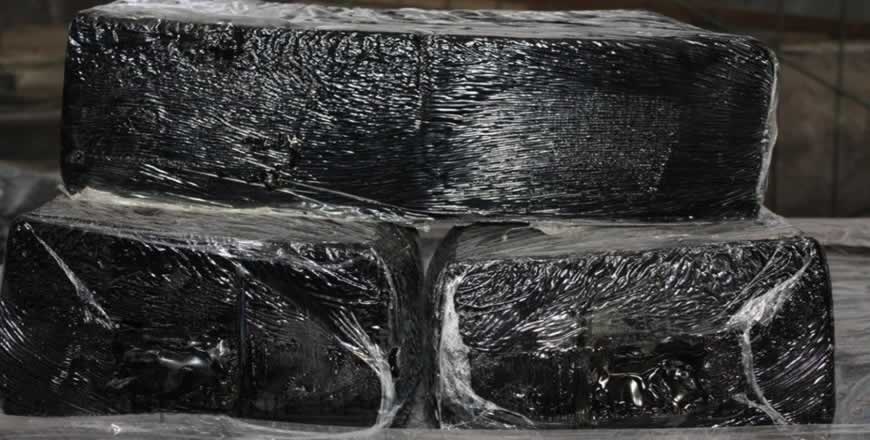

- Packaging: The cooled blown bitumen is packaged into products of various grades.

Technical Considerations and Operational Conditions

Air Blowing Process:

Air is injected into the bitumen from beneath the blowing tank. The reaction between air and bitumen is exothermic, releasing heat as the process occurs.

Temperature Control:

To regulate excess heat generated during the reaction, water may be injected into the tank. This ensures that the temperature remains stable and manageable throughout the operation.

Optimal Conditions:

The ideal temperature for producing blown asphalt is 265–270°C.

Variables such as temperature, air injection rate, reaction time, and pressure in the blowing towers significantly influence the speed and efficiency of the oxidation process.

By maintaining precise control over these factors, manufacturers can produce high-quality oxidized bitumen suitable for various industrial uses.

Applications of Blown Bitumen

Blown asphalt, or oxidized bitumen, has a wide range of applications across various industries, including road construction, water infrastructure, roofing, flooring, the oil and gas sector, and electrical projects. Below, we outline the primary uses of oxidized bitumen and the roles its different grades play.

- Road Construction

Blown asphalt is an excellent choice for road construction, maintenance, and paving. It is widely used as an additive in adhesives for building roads, highways, railways, and parking lots. Its enhanced durability and resistance to environmental factors make it particularly suitable for these applications. - Water Infrastructure Projects

Blown asphalt is a key material in water-related projects. It is frequently used in water canal construction and various other applications, including:- Backfilling and dam construction

- Hydraulic structures and dam covers

- Sand stabilization in erosion-prone areas

- Its water-resistant and stabilizing properties make it ideal for these demanding engineering tasks.

- Roofing

Blown asphalt plays a vital role in roofing applications. It is commonly used in manufacturing:- Roof felts and shingles

- Damp-proofing mixtures

- Gable roof mixtures

- Plastic cement

- Flooring

Blown asphalt is widely used in flooring applications, particularly in industrial settings. Acid- and alkaline-resistant bituminous mastic is utilized to protect floors in chemical factories, fertilizer plants, steel facilities, and other industrial buildings from corrosion. Additionally, oxidized bitumen is highly effective for repairing damaged flooring. - Petroleum and Gas Industry

In the petroleum and gas sector, oxidized bitumen is extensively used to coat pipelines. This provides excellent protection against rust and corrosion, ensuring the durability of infrastructure in harsh environments. - Electrical Power Industry

Blown asphalt is highly adhesive to multi-layered boards, making it a valuable material for:

Benefits of Using Oxidized Bitumen

As demonstrated in the applications above, oxidized bitumen offers a range of advantages, including its versatility, resistance to environmental factors, and protective properties. These qualities make it a critical material across numerous industries.

Exploring Bitumen Uses reveals its versatility in supporting infrastructure and construction industries.

Benefits of Blown Asphalt

Improved Durability

Oxidized bitumen is more durable and resistant to harsh environmental conditions. This makes it a reliable material for use in demanding applications and extreme climates.

Higher Viscosity

The oxidation process increases the viscosity bitumen, enhancing its adhesive properties. This makes oxidized bitumen ideal for applications such as roofing and ceiling insulation, where strong adhesion is essential.

Better Humidity Insulation

Due to its higher viscosity, blown bitumen provides excellent humidity insulation, making it a preferred choice for waterproofing and ceiling applications.

Higher Softening Point

The oxidation process raises the softening point of bitumen, improving its performance at high temperatures. This feature makes oxidized bitumen particularly suitable for use in warm climates.

Enhanced Adhesion

With superior adhesive properties compared to standard bitumen, oxidized bitumen is highly effective for applications in paving, road maintenance, and construction projects requiring robust bonding.

Reduced Grooving and Deformation

The increased hardness of blown bitumen minimizes the risk of grooving and deformation in paved surfaces. This quality makes it an excellent choice for road construction and other high-traffic applications.

Types of Oxidized Bitumen or Blown Bitumen

Blown asphalt products are categorized based on their degree of oxidation, with each grade offering unique physical traits and suited for specific uses. Common gradings include:

Blown Bitumen Grades: Each grade varies in terms of viscosity, softening point, and adhesion properties, tailored to meet different industrial needs.

Important Note: Since the properties of oxidized bitumen vary depending on the manufacturer and intended application, it is crucial to consult a reliable bitumen supplier. Assessing product specifications ensures you select the most suitable blown bitumen for your specific requirements.

Types of Oxidized Bitumen

- Hard-Degree Oxidized Bitumen

This type has the highest level of oxidation, making it ideal for industrial applications that require exceptional resistance to harsh weather conditions. - Medium-Degree Oxidized Bitumen

With a lower oxidation level than hard-degree bitumen, medium-degree products are well-suited for humidity insulation applications, including ceilings, roofs, and building foundations. - Softer-Degree Oxidized Bitumen

Softer-degree blown asphalt has the lowest oxidation level among the types. It is predominantly used in road paving, where its properties are ideal for creating smooth and durable surfaces. - Ultra-Hard Degree Oxidized Bitumen

Similar to hard-degree oxidized bitumen but with an even higher oxidation level, ultra-hard bitumen is designed for use in extreme weather conditions, offering superior resistance and durability.

Difference Between Normal Bitumen and Blown Bitumen

Normal Bitumen:

Normal bitumen is a naturally occurring or petroleum-derived material that is sticky, dark-colored, and versatile. It is commonly used in road construction, waterproofing, and humidity insulation.

Blown Bitumen:

Blown asphalt, or oxidized bitumen, is a modified form of normal bitumen. It is produced by exposing normal bitumen to controlled air-blowing processes at high temperatures. This oxidation process introduces oxygen into the molecular structure of bitumen, altering its physical and chemical properties.

Key Differences:

Production Process:

Normal bitumen: Extracted naturally or refined from petroleum.

Blown bitumen: Modified by blowing hot air into bitumen during controlled oxidation.

Properties:

Normal bitumen: More flexible and less resistant to extreme conditions.

Blown bitumen: Higher softening point, greater viscosity, and increased durability.

Applications:

Normal bitumen: Used in general construction and road applications.

Blown bitumen: Preferred for industrial uses, roofing, and high-resistance insulation.

Bitumen Grades and Standards

Both normal and oxidized bitumen come in various grades, tailored to meet specific applications and regional standards. Choosing the right grade depends on the intended use and environmental conditions. Consulting with a trusted supplier ensures the selection of the best product for your needs.

Comparison of Normal Bitumen and Blown Bitumen

Consistency

Normal bitumen is naturally hard and highly adhesive. However, blown bitumen is even harder but less adhesive due to the oxidation process, which increases molecular weight and cross-linking. This change results in a more solid consistency for oxidized bitumen compared to normal bitumen.

Softening Point

The softening point of bitumen indicates the temperature at which it becomes soft and flexible. Oxidized bitumen has a higher softening point, making it more suitable for high-temperature environments and roads with heavy traffic.

Durability

Blown asphalt’s increased molecular weight and enhanced cross-linking provide greater durability. It is more resistant to temperature fluctuations, ultraviolet rays, deformation, and cracking, ensuring a longer lifespan under challenging conditions.

Usages

Normal Bitumen: Commonly used in road construction, paving, humidity insulation, and asphalt production.

Blown Bitumen: Ideal for applications requiring higher hardness and resistance, such as roofing materials, pipeline covers, electrical insulation, and joint fillers.

Accessibility

Normal Bitumen: Readily available from natural resources or petroleum refining processes.

Blown Bitumen: Manufactured through a specialized process involving controlled air blowing in production plants, making it less naturally accessible.

Where to Buy Oxidized Bitumen

Blown asphalt stands out for its water resistance, flexibility, durability, and chemical stability. These properties make it a vital material in numerous industries.

If you are looking to purchase oxidized bitumen, many manufacturers and suppliers specialize in its production and sale. For pricing and inquiries, feel free to reach out to us at PetroBNX, your trusted supplier for high-quality blown asphalt products.

No comment