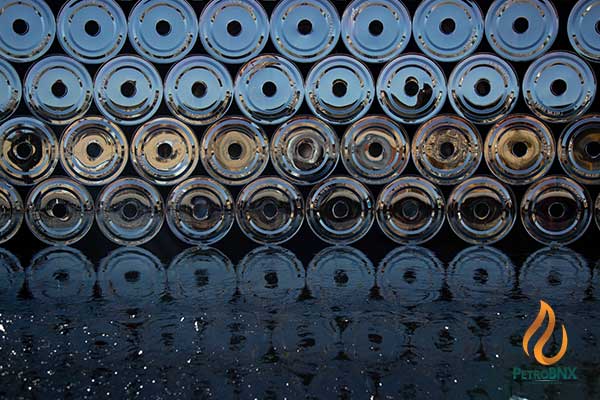

Bitumen Drum, also known as barrel bitumen, is a widely-used packaging method that ensures easy transportation and storage. It is highly favored for construction and industrial applications due to its convenience and practicality.

In this article from PetroBNX, we provide a comprehensive guide to purchasing drum bitumen. From pricing and types to the advantages of barrel bitumen and key considerations for buyers, you’ll find all the essential information here.

Bitumen is an immensely viscous constituent of petroleum.

Buying Drum Bitumen: How to Purchase Barrel Bitumen?

Purchasing bitumen drum requires careful consideration of factors like the grade of bitumen (e.g., 60/70, 85/100), packaging quality, and supplier reliability. At PetroBNX, we simplify the process by offering high-quality drum bitumen sourced from trusted manufacturers. Contact us to explore flexible purchase options tailored to your needs.

Barrel bitumen, named for its packaging, is stored in metal drums to ensure easy transportation, efficient storage, and proper preservation. This method protects bitumen’s unique properties, such as high adhesiveness, while preventing degradation due to environmental exposure.

Major Suppliers of Barrel Bitumen

- Petrochemical Companies: Some petrochemical companies supply drum-packaged bitumen.

- Bitumen Manufacturers: Leading producers in Iran offer high-quality bitumen in metal drums.

- Road Construction Material Factories: These factories often include barrel bitumen in their product range.

- Online Wholesale Platforms: Websites like PetroBNX act as intermediaries, offering competitive pricing for drum bitumen.

- Importers and Exporters: Trading companies specializing in bitumen trade provide efficient solutions for global buyers.

- Trade Shows and Conferences: Events focused on construction and road-building connect buyers with top manufacturers.

Types of Drum Bitumen and Applications

Drum packaging ensures bitumen remains uncontaminated, prolonging its shelf life. Barrel bitumen is particularly useful in:

- Asphalt Paving: Roads and airport runways.

- Waterproofing: Roofs and structures.

Common Types of Drum Bitumen

- Bitumen Drum 60/70: A penetration-grade bitumen with moderate hardness, ideal for temperate to warm climates. It offers high

- adhesiveness and resistance to moisture, making it perfect for highways and high-traffic zones.

Types of Drum Bitumen

Mixed Bitumen 85/25

- Penetration Grade: 85

- Softening Point: 25°C

Mixed Bitumen 85/25 offers a balance of flexibility and low softening point, making it suitable for thermal and moisture insulation in buildings and underground structures. It is widely used for producing mastics and sealants due to its high adhesiveness and flexibility in cold weather, preventing cracking.

Bitumen Emulsion

- Composition: Bitumen, water, and emulsifying agents

- Key Features:

- Low viscosity

- No heating required (energy-efficient)

- Environmentally friendly

Bitumen emulsion is ideal for cold asphalt production, enabling road construction at ambient temperatures. Its strong adhesiveness makes it a preferred choice for applications requiring quick, durable bonding.

Blown Drum Bitumen

- Production Process: Air-blowing pure bitumen to enhance its physical properties

- Applications:

- Roof plates

- Waterproofing membranes

- Additives for rubber and plastic industries

Blown bitumen boasts a higher softening point and excellent resistance to flow and deformation, making it suitable for high-temperature environments.

Drum Bitumen MC (Medium-Curing)

- Composition: 64% bitumen combined with petroleum solvents

- Applications:

- Prime coat for road surfaces

- Cold asphalt production

MC bitumen is valued for its slow-setting properties, providing adequate curing time for construction and road-building processes. It ensures optimal adhesion between asphalt layers, enhancing durability.

For inquiries about drum bitumen pricing or product specifications, contact PetroBNX to find the ideal solution for your project requirements.

How is the Price of Drum Bitumen Specified?

The price of bitumen drum depends on multiple factors that collectively determine its market value. Key considerations include:

- Type and Quality of Bitumen

The type (e.g., pure bitumen, blown bitumen, emulsion bitumen, or MC bitumen) and quality directly affect pricing. - Market Demand and Supply

High demand or limited supply can lead to price increases, while abundant supply and low demand may reduce prices. - Crude Oil Prices

Bitumen being a petroleum product, its price closely follows crude oil price trends. - Production Costs

Factors like refining, manufacturing, packaging, and energy costs significantly influence the final price. - Transportation Costs

Exporting bitumen to distant markets increases transportation expenses, affecting the overall price. - Exchange Rates

Currency fluctuations play a significant role in international pricing. - Economic and Political Conditions

Global economic trends, sanctions, and regulations can impact prices. - Seasonal Demand

Prices typically rise during peak construction seasons like spring and summer. - Technological Advancements

Innovations in production technology can reduce costs and influence pricing trends.

Price of Mixed Bitumen Drum

Mixed drum bitumen is a polymer product, and its price depends on factors like raw material costs, production expenses, and packaging. The type and composition of mixed bitumen also contribute significantly to its final price. Comparing supplier prices ensures the best deal.

Price of Soft and Hard Drum Bitumen

Soft Drum Bitumen: Influenced by production costs, crude oil fluctuations, and packaging expenses. Prices vary across markets and are subject to periodic changes.

Hard Drum Bitumen: Determined by type, quality, and market conditions. Prices often update daily to reflect market dynamics.

For detailed and up-to-date pricing, contact PetroBNX or your trusted supplier.

Price of Hard Carton-Packed Bitumen

The cost of hard bitumen in carton packaging differs from drum-packed bitumen due to various factors:

- Packaging Type

Carton-packed bitumen generally costs less due to reduced production and handling costs.

Drum-packed bitumen has higher prices because drums are designed for durability, preserving quality during transport and storage. - Transportation Costs

Carton packaging is more compact and lighter than metal drums, reducing shipping costs. - Volume and Quantity

Carton-packed bitumen typically contains smaller quantities, making it cost-effective for projects requiring limited bitumen.

Drums are suited for bulk storage and transportation, reflecting higher costs. - Storage and Usage

Drums maintain bitumen quality over longer periods, making them suitable for industrial use.

Cartons, although cheaper, may not provide the same level of protection against environmental factors.

Price of 220-Litre Drum Bitumen

The price of 220-litre drum bitumen depends on:

- The type of bitumen (e.g., 60/70, 85/25, or other grades).

- Raw material costs, especially crude oil prices.

- Production and packaging expenses.

- Demand and supply levels in local and global markets.

- Exchange rate fluctuations, particularly for export.

For the latest pricing, check with PetroBNX, which offers competitive rates and detailed comparisons across suppliers.

Price of 60/70 Drum Bitumen

- Crude oil prices have the most significant impact on the price of 60/70 bitumen.

- Production costs, including refining and packaging in 220-litre drums.

- Transportation expenses for domestic and international shipping.

- Demand in markets with temperate to warm climates, where 60/70 bitumen is commonly used for road construction.

Contact PetroBNX for up-to-date quotes on 60/70 drum bitumen.

Price of 85/25 Drum Bitumen

- The price of 85/25 drum bitumen varies with production costs and market conditions.

- Sanctions and global economic volatility have caused price increases of 10-20% in recent years.

- Prices are generally calculated per kilogram or ton.

How to Order Drum Bitumen

Step 1: Identify Needs

- Determine the type of bitumen (e.g., pure, blown, emulsion, mixed) based on project requirements.

- Consider packaging type (drum or carton) and specifications (penetration grade).

Step 2: Determine Quantity

- Calculate the number of drums required for your project or use case.

Step 3: Research Suppliers

- Look for reputable suppliers through online platforms like PetroBNX, industry directories, or trade shows.

Step 4: Price Inquiry

- Request quotes from multiple suppliers to compare prices, terms, and delivery options.

For a hassle-free experience, reach out to PetroBNX, where experts can guide you through the ordering process and provide competitive pricing for all types of bitumen drum.

Most Important Features of Drum Bitumen

Drum bitumen is a preferred material in construction and road-building due to its unique characteristics, which include:

- Viscosity

Refers to the stickiness and flow resistance of bitumen.

Different types offer varying viscosities tailored to project needs. - Waterproofing

Naturally prevents water penetration, making it ideal for roofs, foundations, and other moisture-sensitive surfaces. - Resistance to Weather Conditions

Withstands rain, snow, UV rays, and temperature changes, ensuring durability in roads and building coatings. - Chemical Resistance

Resists exposure to chemicals and pollutants, suitable for industrial and contaminated environments. - Adhesion

Creates a strong bond with various surfaces, essential for repairs, sealing, and asphalt applications. - Thermal Stability

Maintains its properties across temperature ranges, ensuring usability in diverse climates. - Easy Transportation

Drum packaging ensures safe and contamination-free transport, particularly to remote locations. - Drying Time

An optimal drying time is crucial for project scheduling and follow-up operations.

Weight of Drum Bitumen

The weight of drum bitumen depends on the drum’s volume and the bitumen’s density.

- Standard drum volume: 220 litres (55 gallons).

- Bitumen density: Typically ranges between 1.0 to 1.2 kg/L, depending on type and temperature.

- Typical weight: A 220-litre drum weighs 240–260 kg, including the drum itself.

Calculation Formula:

Weight of bitumen = Barrel volume × Bitumen density

Types of Drum Bitumen for Construction

- Pure Bitumen (Soft Bitumen)

- Penetration grades: Commonly Bitumen 60/70 or 85/25.

- Applications: Asphalt production, road paving, and construction sublayers.

- Blown Bitumen

- Produced by blowing air through liquid bitumen.

- Penetration grades: 40/50 to 70/100.

- Applications: Protective layers, insulation coatings, and high-resistance asphalt.

- Bitumen Emulsion

- A liquid form mixed with water and emulsifiers.

- Applications: Sealing, surface repairs, and soil stabilization.

- Modified Bitumen

- Enhanced with polymers for improved properties.

- Applications: Insulation layers, roof coatings, and projects requiring temperature/weather resistance.

For construction projects, selecting the correct type of drum bitumen ensures durability, efficiency, and long-lasting results. Contact PetroBNX for expert guidance and high-quality options tailored to your needs.

No comment